Here are the pics, as promised.

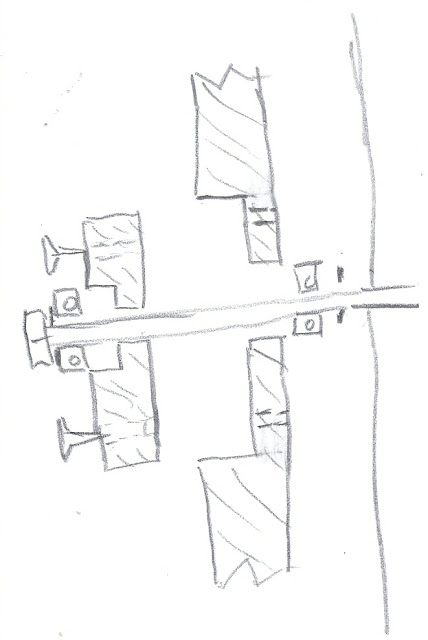

Just finished a tilting-top table for unloading the router. Idea here is to pull the sheet of still-tabbed cut parts off the machine in one smooth motion -- without breaking the tabs and ruining parts as I was doing. This is nothing more than a folding table, lightly reinforced, with a hinged top made of two pieces of 3/4" plywood. One is a chewed up old piece so I can chisel and route on it with no consequences.

- tilting_table_DSC01636.jpg (50.72 KiB) Viewed 10604 times

Here is my new dust shoe. I used to use a KentCNC dust shoe, but found that I just couldn't clear the chips when using a downcut router bit. After a lot of tinkering I realized that basically I just needed to reduce the overall surface area of the dust shoe and get the vac hose as short and as close to the router bit as possible. Most of this thing is made from a 4" to 5" hose adapter from Rockler that I had lying around. I sawed the top off and lasered an adapter that fit it to the spindle of my router. The temporary skirt you see is made of Gorilla Tape. Which, my friends, is awesome, awesome stuff and I highly recommend it for any task you may have once thought duct tape was good for.

- new_dust_shoe_1_DSC01640.jpg (29.36 KiB) Viewed 10604 times

Here you can see the inside of the shoe. It is apparent that it is comprised mostly of hot glue and hope.

- new_dust_shoe_2_DSC01637.jpg (33.59 KiB) Viewed 10604 times

Here you can see my quick-release attachment scheme - just some flat-topped bolts which positively lock in some registration holes and stick to some surplus hard drive magnets.

- new_dust_shoe_3_DSC01638.jpg (32 KiB) Viewed 10604 times

Here you can see the attachment plate which is itself magnetically attached to the spindle.

- new_dust_shoe_4_DSC01639.jpg (26.1 KiB) Viewed 10604 times

Eventually this thing will break or need replacement. The biggest problem with it is just that it hangs very low - if the spindle were to crash it would break. I will do my best to avoid that circumstance.